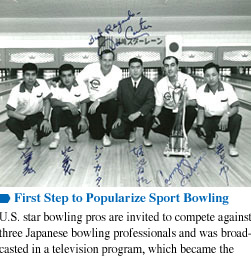

In 1962 Tomoji Horiike established an importing company of bowling equipments. Many leaders of business world including the president of Mitsui Bussan Co. Ltd. supported his venture for the popularization of bowling as a family sport. Two years later he began to operate bowling centers named Starlanes and organized the world largest franchise bowling chain throughout Japan. He gave birth to professional bowlers in Japan and invited American leading pro-bowlers to introduce real dynamic bowling to Japanese fans. PBA's authorized tournament Japan Cup and PWBA's Pearl Cup sponsored by Mikimoto Pearl were roadcasted through TV. (Later Starlanes changed its company name to "Diamond Star").

However these efforts began to push Japanese bowing to an unexpected direction partly because of lady's pro- bowling boom. Bowling programs for just amusement were on air day after day and bowling center was constructed one after another. The result of over-supply was apparent. We repeatedly warned the industry but it was impossible to restraint them. Especially big companies found their way into bowling business as their side line. Then we decided to start action by ourselves and sold out our bowling centers in the midst of the bowling boom.

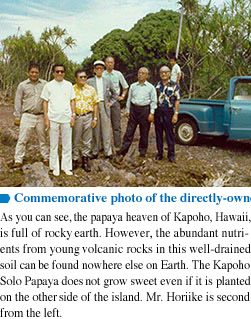

The first business after we bid farewell to bowling was an investment in the papaya farm. It was a failure. But we found it was due to the poor management of the operator, we decide to set up our own papaya plantation and packing shed. Especially in order to meet Japanese consumer's fussy requirements we thought we need to participate in the starting point of production. This policy (we call Develop and Export) has been applied to all of our export companies. It is not always appropriate to have our own farm, but we make it a rule to participate in the production side even by running a pilot farm.

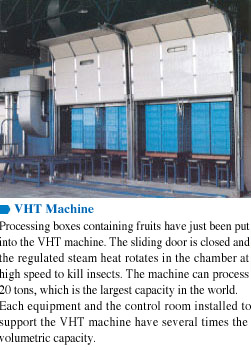

It was the year of 1986 that the turning point came. The Japanese Agricultural Ministry advised us that the EDB, a very effective insecticide against fruit flies would be banned in a year or two because of its harmful effects to human beings. They suggested us to prepare some alternative measures and showed two options, Hot Water Dip or Vapor Heat Treatment and the officer added that Hot Water Dip is easy and cheap but there is a problem in treatment certainty, meanwhile VHT is reliable but expensive. We chose VHT without hesitation and started to develop the machine and system jointly with the plant division of Takenaka Corporation. A prototype of the machine was completed shortly however we found it very difficult to kill flies (the most strong egg stage) without killing fruit by the heat of more than 46 degree C. As there is no more read scale than 43 degree C on clinical thermometer, for all creatures it is very dangerous to be exposed to such a high temperature for many hours. After many trials and errors, we could establish the system by computer programming and succeeded in the VHT of papaya. It may be difficult to imagine that we need a factory equipped with huge machines controlled by computer just for the export of tropical fruits.

This pioneering technology and know how led us to handle many tropical fruits from around the world.

![]()